Rubber bonded wheels are wheels that are made by bonding a layer of rubber onto a metal core or hub. The rubber layer provides a cushioning effect that absorbs shock and reduces vibration, making them ideal for use in applications where a smooth ride is important, such as in industrial carts, hand trucks, and other material handling equipment.

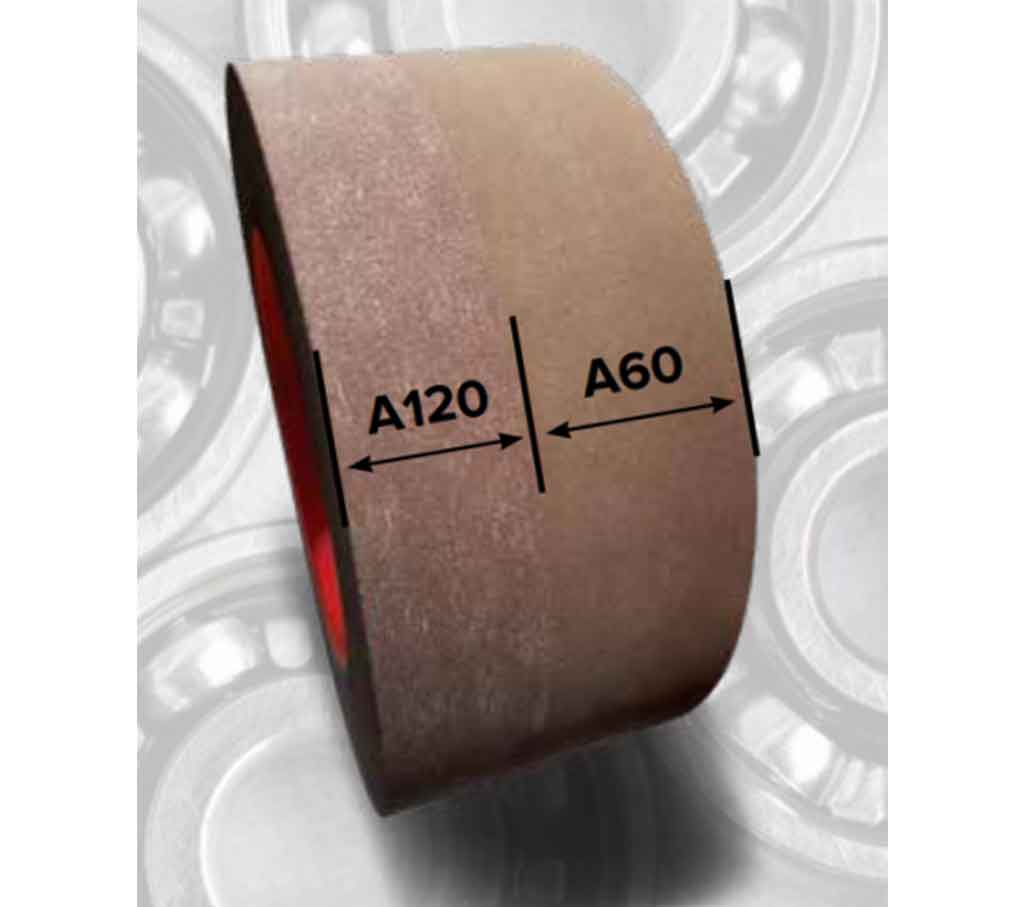

Rubber bonded wheels are available in a range of sizes, shapes, and durometers (hardness ratings), and can be customized to meet specific requirements. They are also resistant to chemicals, oils, and greases, making them suitable for use in harsh environments.

Rubber bonded wheels are commonly used in a variety of industries, including aerospace, automotive, construction, and manufacturing. They are particularly useful in applications that require heavy load capacity, impact resistance, and durability.

Overall, rubber bonded wheels offer a number of advantages over other types of wheels, including improved shock absorption, reduced noise and vibration, and increased traction and grip.